The automotive industry's foundation rests on a massive, intricate supply chain that demands absolute precision…

July 30, 2024

Embracing the future: Logistics solutions for robotics manufacturing

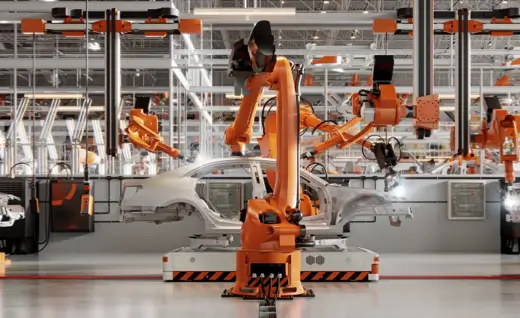

The robotics industry is making manufacturing more efficient and more profitable than ever. Together with Artificial Intelligence (AI) technology, robotics enables factories to speed up the assembly process and produce higher quality goods at much lower costs.

With the promise of improved margins and greater efficiency, it’s unsurprising that a growing number of companies around the world are turning to robotics.

The International Robot Federation reported a record installation of over half a million industrial robots in 2021, with the total operational stock of robots worldwide reaching approximately 3.5 million units, according to a report by Statzon.

Robotics is not just the future; it is the present

And yet, there are challenges too. Manufacturing is subject to economic headwinds like all other industries. In 2023, for the first time in five years, the uptake in robotics hit a speed bump.

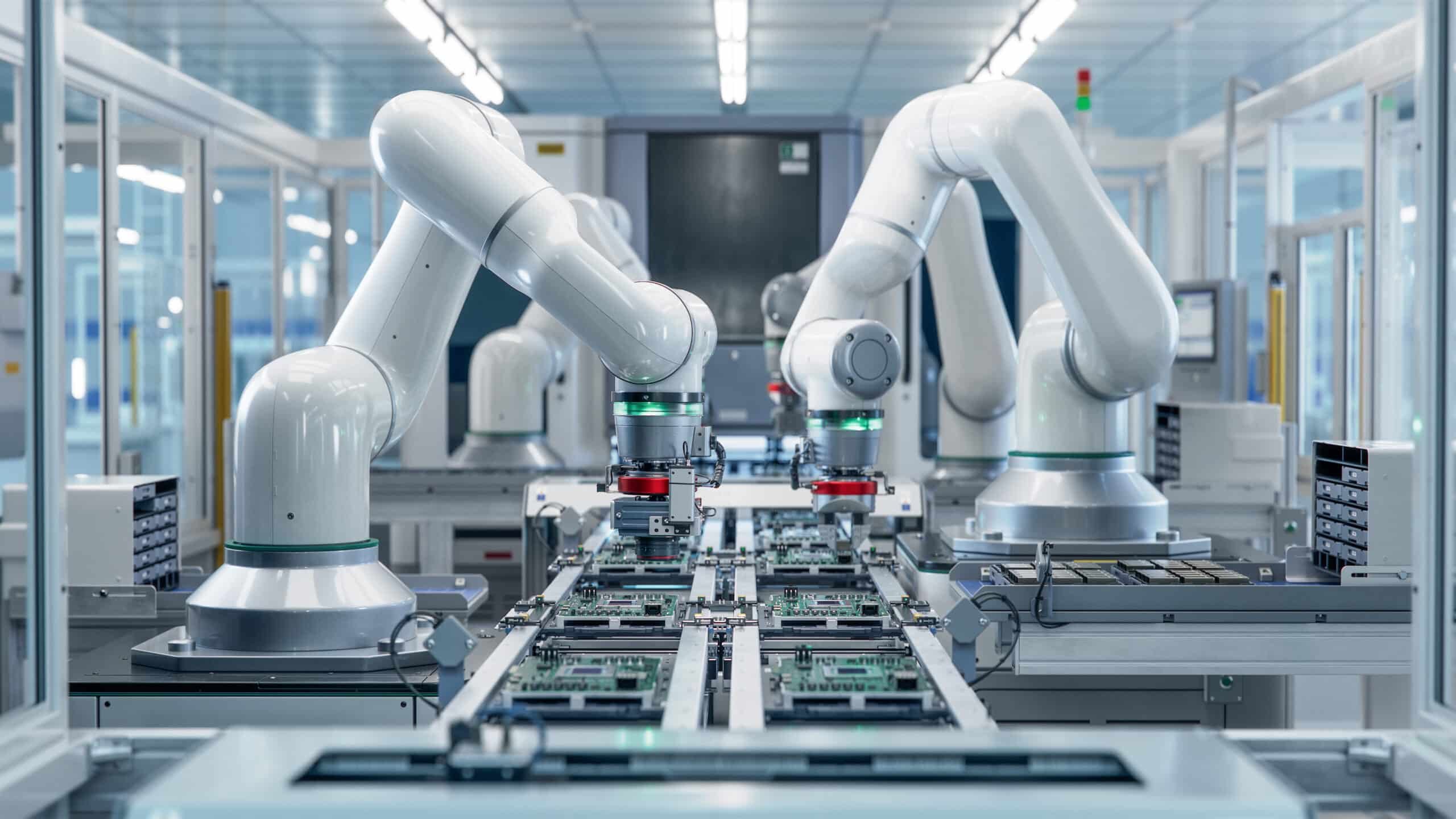

One of the main challenges for companies using robotics is their logistics and supply chain. The use of robotics has expanded so rapidly, most supply chain partners have not been able to get up to speed. It’s an innovative industry that requires dynamic solutions.

Unreliable supply chains cost money. In the Annual Global Supply Chain Report by Interos, disruptions cost the surveyed companies an average of €168 million annually in lost revenue.

Challenges and opportunities

Robotics requires very specific parts and components such as sensors for environmental awareness and actuators for physical movement.

As a result, factories often find themselves hampered by their supply chain. If a critical part malfunctions on one of the robots, everything comes to a grinding halt as they await a replacement. Waiting for spare parts costs money and causes delays, unhappy customers, and potentially leading to lower customer retention. A well-structured warehouse logistics network ensures that critical parts are always stocked in strategic locations, enabling faster dispatch and reducing downtime, combined with final mile logistics this makes sure that these essential components reach engineers and factories swiftly and keeps operations running smoothly.

In a study by Voxware, 69% of customers surveyed were ‘much less’ or ‘less likely’ to return to a retailer if the goods were not delivered within the promised timeframe. The same is surely true across all industries.

Carousel has several ground-breaking solutions to get the replacement parts to you as soon as possible.

- By:Night – with overnight delivery you are no longer constrained by normal working hours. Parts will be on-site before 08:00

- Pick up and Drop off (PUDOs) locations – access to hundreds of strategically placed PUDO locations allows engineers to collect and drop return parts to suit their schedule. Arrange delivery to your nearest PUDO location so you can manage your time and supply chain to suit your schedule

- Warehouses – we have warehouses across Europe, so we can deliver from the one that’s nearest to you

- Tracking – monitor your delivery with live GPS tracking. This allows you to proactively plan for its arrival.

- Precise delivery – we get critical parts to exactly where they are needed whether that be the boot of an engineer’s van or to a specific room in a factory.

All the above makes your supply chain resilient. An overnight delivery will save you money and get you back on track, with live tracking and precision delivery to give you peace of mind, and strategically located warehouse hubs to make every second count.

We are meeting the rising demand for efficiency in the core sectors that utilise robotics – manufacturing, logistics, agriculture, construction, and other industries.

Sustainability

Sustainability is about more than just helping the planet. It’s also about your bottom line. Increasingly, customers want to buy and use services from companies that align with their own ethics.

By increasing your company’s efficiency with the use of robotics, you are reducing your carbon footprint, doing your bit for the world, and creating opportunities to work with new customers searching for ethically minded brands.

Equally, by partnering with Carousel, you will be working with an environmentally conscious partner, committed to sustainable logistics and reducing our carbon footprint through operational efficiency. Our precision deliveries improve efficiency and reduce unnecessary driving time or pick-ups, lowering our environmental impact.

The future

Robotics are set to increase your overall operational efficiency by saving you time and money. But without a functioning, resilient, supply chain, robotics in manufacturing can cause problems too.

Waiting for critical parts can lead to significant delays in manufacturing schedules as production comes to a halt. Even if only one part of the assembly line is affected, it can create bottlenecks that slow down the entire manufacturing process.

With Carousel, you can rest easy, knowing that your trusted partner can guarantee you faster access to spare parts, giving you a more efficient and resilient supply chain.

Want to know more?

To learn more about the role of time-critical logistics in robotics for manufacturing, get in touch with our team.