In the UK, 95% of construction projects reported delays in 2024, pushing costs up by…

September 17, 2025

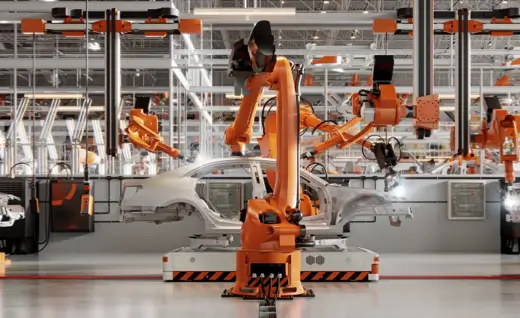

Loose loading in automotive logistics: what you need to know

The way cargo is loaded, transported, and unloaded can optimise operational efficiencies in a supply chain. One option for delivering cargo more efficiently is loose loading. It’s a method that has its advantages, particularly in sectors like automotive, where spare parts and products are all different shapes and sizes.

Below, we’ll guide you through what loose loading is, the benefits it offers, some concerns, and why it matters to logistics managers shipping large quantities of cargo across Europe.

What is loose loading?

Loose loading is the practice of placing cargo directly into containers or trailers without pallets, cages, or crates. Instead, parts or products are packed individually, often in smaller boxes or wrapped securely, and then carefully stacked to make full use of the available space.

In the automotive sector, the traditional method has been caged or palletised loading for spare parts. While this might appear more secure, in practice, it often causes more damage and losses as parts can shift during shipment. Using cages can also lead to unused space and higher transportation costs because loads are not maximising space.

By contrast, loose-loaded cargo can be packed according to the specific requirements of each component. This creates a more tailored and space-efficient system that reduces damage, cuts down on deliveries, lowers carbon emissions, and drives cost savings across automotive supply chains.

The points of interest of loose loading

Like any logistics method, loose loading comes with its challenges, and it isn’t always the right fit for every shipment. The challenges of loose loading include:

Transit instability

There is a common misconception that loose loading means that items are free to move around in the vehicle during transport. This isn’t the case. Loose loading simply means that the items are not palletised or in cages. They are either bolted or strapped securely in place to minimise movement during transit. This ensures that transportation is safe while reducing the space that each part takes up.

Efficiency pressures

With proper planning, loose loading is key for efficient handling. Without the right systems in place, unloading loose-loaded containers can take longer. But when compared to cages, which frequently leave wasted space forcing more trips, loose loading often comes out ahead in terms of overall efficiency.

Cost considerations

More time and labour naturally add cost, and loose loading can appear more expensive at first glance. But the reduced damage rates, better use of available space, and fewer losses often make it the more cost-effective choice in practice, particularly for high-value or irregularly shaped parts.

The benefits of loose loading

Loose loading isn’t just a space-saving exercise; it brings a number of advantages that are particularly relevant to industries like automotive, where spare parts come in every shape and size.

Maximum use of space

Because parts aren’t restricted to cages or shipping pallets, they can be packed tightly within containers or trailers. This reduces wasted space and helps lower transportation costs while keeping spare parts safe.

Reduced damage and losses

With loose loading, each part is boxed or wrapped individually, then fitted into the available space with greater care. This approach actually reduces the risk of shifting, breakage, or scuffing compared to caged systems. A big advantage for valuable automotive components.

3. Greater flexibility

From small bolts to awkwardly shaped panels, automotive shipments include a wide variety of parts. Loose loading makes it possible to adapt easily to different sizes, shapes, and specific needs, without forcing parts into a one-size-fits-all cage or pallet. This is why it’s ideal for professional vehicle spare parts logistics. It’s a shipping method that can adapt to any load, whether it’s millions of nuts and bolts or fragile, yet bulky, EV batteries.

4. Faster loading and unloading

By removing the additional stage of palletising, loose loading can actually speed up operations. Parts can be loaded more directly, and in many cases, the unloading process is streamlined too, particularly when supported by the right handling equipment. For high-volume automotive flows, this efficiency gain is significant.

How loose-loaded cargo is transported

Loose-loaded freight isn’t limited to one type of vehicle. Depending on the nature of the cargo, we may use:

- Flatbed trailers – ideal for oversized loads or goods that need to be secured with straps.

- Step deck trailers – useful when cargo height would otherwise exceed legal limits.

- Removable gooseneck trailers – designed for easy loading and unloading of construction equipment and heavy machinery.

- Low-loader or low-bed trailers – essential for massive loads that need stability during transportation.

- Specialised trailers – for cargo with unique requirements.

In each case, the type of handling equipment and unloading process will vary, but the principles are the same: ensure goods are handled safely, efficiently, and with minimal risk of damage.

Practical considerations for logistics managers

If you’re deciding whether loose loaded cargo is right for your shipment, here are some points to weigh up:

- Packaging: Will smaller boxes or bags provide enough protection for your parts, or is palletisation needed?

- Warehouses: Are the origin and destination facilities equipped with the right handling equipment to deal with unloading safely and correctly?

- Space efficiency: Will the load actually make better use of available space if shipped loose?

- Cargo needs: Is this a one-off shipment or are there ongoing delivery requirements that make palletisation more practical?

- Supply chain impact: How will loading and unloading loose-loaded containers affect wider logistics performance and efficiency?

Please get in touch to discuss your shipments and whether loose loading is right for your spare parts. Choosing the right shipping methods, whether palletised, bulk, or loose, can influence everything from cost and efficiency to customer satisfaction.